How to Install Hardwood Floors Over Radiant Heat

Parquet floors are readily used in radiant heat applications. With strip flooring, the wider the board, the greater the potential for gaps between the boards when they contract with seasonal changes in temperature and humidity. Tongue-and-groove strips are recommended and beveled-edge boards show fewer seasonal gaps.

Sanding produces highly flammable dust, so remember to seal the doorways into your work area with plastic and ventilate the area with a fan. While sanding, wear goggles, ear protection and a dust mask. And when applying the finish, wear goggles, rubber gloves, long pants and a long-sleeve shirt, for added protection.

It isn’t recommended to use radiant floor heating under plank flooring wider than 3″. Despite all your precautions, there is a high probability the user will not be satisfied.

How It Works

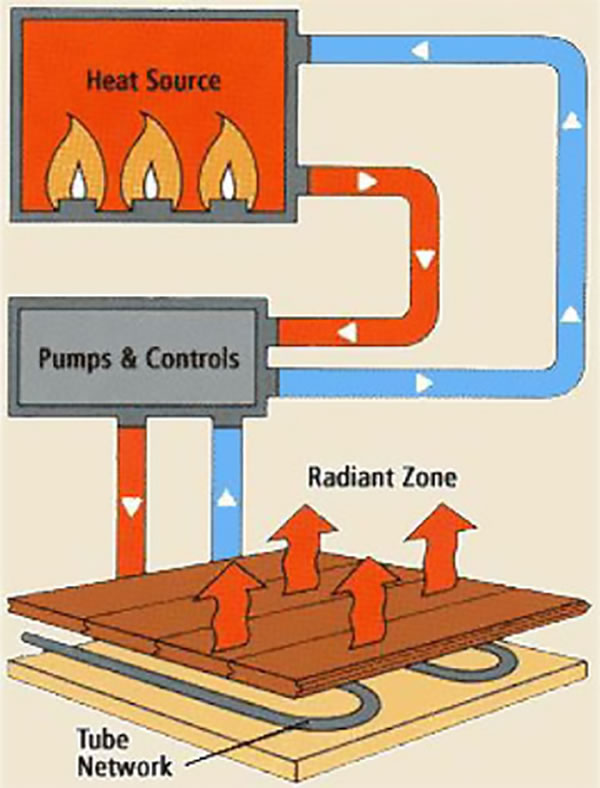

Radiant heat systems use a three-stage process to convey heated water to its destination. (See diagram).

- A water heating system that can be either a standard boiler, water heater, a geothermal heat pump or even solar panels.

- The heated water is pumped through a tubing network installed in the subfloor.

- As the warm water moves through the tubing network, it releases its energy and returns to the boiler system to be reheated.

Installation Details

Good communication with the radiant heat system designer is critical. Everyone should be notified of any work pertaining to the installation, especially if specifications are changed.

To ensure a superior end product, pay attention to the following factors before, during and after installation:

Subfloor

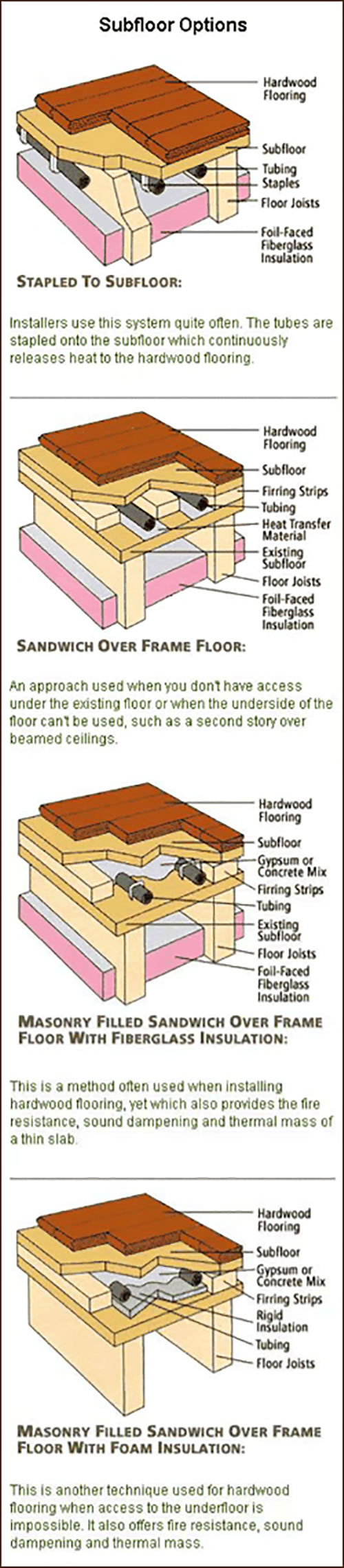

Work with the system designer to choose the subfloor option (see illustrations.) The heat system designer is responsible for the subfloor installation, but you will want to be familiar with the choices. Direct contact of the tubing with the flooring is not recommended. The subfloors shown here are recommended for hardwood floor installations. Plywood (5/8″) or oriented strand board (3/4″) make good candidates for subfloor materials in radiant installations. Particleboard subfloors are not recommended by radiant heat companies.

Floor Temperature

Provide the radiant heat system designer with the hardwood flooring dimensions, species, and the desired temperature of each room. This will give him/her the information needed to calculate the necessary water temperature.

Tube Installation

Consult with the system designer to determine the tube network layout, so you’ll know where the tubes are before you nail down the floor. It is best to have the tubing spaced evenly down the joist cavity (between the sleepers). Then you can nail down the finished flooring onto the sleepers on eight-inch centers. When the tubing circuits are crossed over the center of the joist cavity, have the system designer use nail plates to protect the radiant circuits from being punctured.

Climate Controls

The following climate controls will minimize expansion and contraction during and after installation of the floor.

Mechanical Humidity Control: The heating-ventilation-air conditioning (HVAC) system should have mechanical humidity control. This will monitor the room and keep the relative humidity at an even level, which will keep the equilibrium moisture content of the floor stable.

Heat Transfer Point Control: The system designer also should install a set point control that will monitor the wood floor temperature. The set point control should either reduce the system water temperature or temporarily cycle the system off to prevent overheating the flooring if equipment malfunctions.

Exterior Thermostat: An exterior thermostat is recommended to protect the perimeter of the system from condensation absorption during the spring and fall when rapid temperature changes may occur.

Once the subfloor, tubing and climate controls have been installed, the heating system should run for at least 72 hours to bring the house to the desired relative humidity.

Temporary, unvented sources of heat – such as propane-fired “salamanders” – can add excessive amounts of water vapor. Avoid them if possible, but if they must be used, leave windows open to vent the humidity.

Now follow the customary procedures for installing any hardwood floor.

Technical assistance and/or photos provided by; HeatLink USA Inc., Grand Rapids, Mich.; Heatway, Springfield, Mo.; Wirsbo, Apple Valley, Minn.