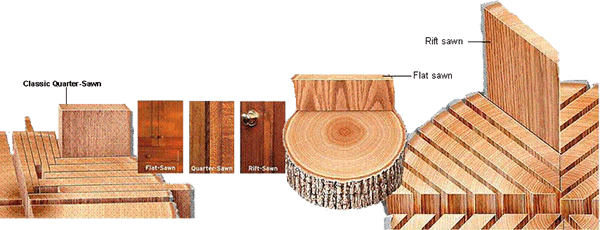

Sawing Methods

Different sawing methods, i.e. at what angle the saw meets the log’s growth rings, determine the grain pattern or figure unique to each log.

Plain Sawn

At least 95 percent of all hardwood lumber commercially produced in the U.S. is flat or plain sawn. With this sawing method, which yields the most lumber and produces the widest possible boards with the least log waste, growth rings are parallel to the board’s surface, creating the distinctive flame-shaped, arch or cathedral grain pattern. Of all the sawing methods, it is the most cost effective.

Quarter Sawn

In this method, the log actually is cut into quarters, then sawn quarter by quarter. A single board is sawn from one face. The next board is sawn from the opposite face and the sawing proceeds on alternate faces. The growth rings are perpendicular to the board’s broad face, producing a vertical and uniform grain pattern. This sawing method, which yields fewer and narrower boards per log, is a slower and thus more expensive process, boosting the cost of quarter sawn lumber significantly.

Rift Sawn

In this method, the log is again cut into quarters. Each quarter is then sawn with the growth rings at 30 to 60 degree angles to the board surface. This produces a vertical or straight grain appearance that is easily confused with quarter-sawn. Also similar to quarter sawn, rift sawn boards are narrower, available in limited quantities, and the sawing method produces a significant amount of log waste.

No matter how you slice it, American hardwood is a cut above.