American Hardwoods: Ash

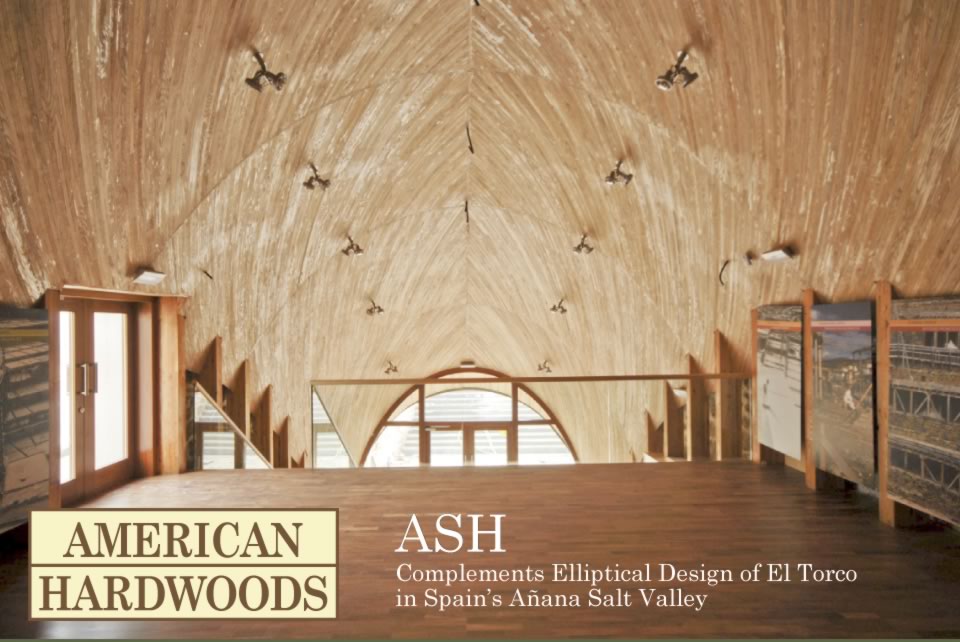

Complements Elliptical Design of El Torco in Spain’s Añana Salt Valley

Photo courtesy the American Hardwood Export Council.

For the team at Spanish architectural firm Landa-Ochandiano, American ash was the natural choice for a building that stands as a testament to one of Spain’s oldest industries—salt production. In 2003, restoration began on some of the buildings between the town of Añana and the Añana Saltworks. An old salt store, with perimeter walls as its only remnants, became El Torco, an aesthetically appealing design mix of old and new elements and an amazing testament to the flexibility of American ash.

The ancient Añana Saltworks are a result of a geological phenomenon called diaper, which creates hyper-saline springs. Salt making activity in Añana was continuous from 822 until the end of the 20th century (although some date its origins before the ninth century), when the buildings were abandoned and consequently fell into disrepair. The former salt store, now known as El Torco, opened in 2008 as the visitors’ centre and hosts exhibitions and guided tours of what had been an important industry for the area.

Architect Mikel Landa’s inspiration for the design and choice of materials came from his experience of building his own kayak. Thus, El Torco’s shape resembles an upside down boat’s hull. According to Landa, “American ash offers a light tone and marked grain, which provides the visual effect we were looking for. It is strong, relative to its weight, and is flexible,” noted Landa. “We cut the ash into small strips, which allowed for the bending needed to take on the unique shape of the building’s skin.”

Two layers of American ash connect 17 vertical arches, made of laminated American larch. One layer of ash is fixed to the underside of the arch members and forms the visible interior, while the other layer is fixed to the upper face of the arch members. Sandwiched between the two layers of ash is a layer of stone wool, a by-product of volcanic activity that repels water, is resistant to fire and mildew, and has excellent sound absorption and thermal properties. A curved dovetail was used so that the fit of one board with the next allowed for a slight turn between boards. The edges were glued during fitting and the surface was sanded to give its final appearance.

In addition to American ash, other hardwood species were used in the project, with specific building materials being selected because of the corrosive hyper-saline environment. “Wood was used as interior and exterior sheathing, joinery and some flooring,” noted Landa. “The use of the different wood species, in line with their individual mechanical and aesthetic characteristics, produced a unique building that serves as a testament to the adaptability of these naturally sustainable materials.”

Photo courtesy the American Hardwood Export Council.